Fashion’s addiction to fossil-fuel-based fabrics is no longer just unsustainable, it’s creatively bankrupt. For an industry obsessed with reinvention, it’s shocking how little has changed at the fibre level. Polyester still rules, leather still pollutes, and most “eco” solutions are just rebranded waste. But behind the scenes, a quieter revolution is unfolding, one that begins at the molecular level. Materials made from microbes, beer waste, and butterfly wings are challenging everything we know about textiles.

YUNG rounds up the names you’ll want to remember because they’re not just shaping the runway, they’re shaping the very materials our favourite pieces are made of.

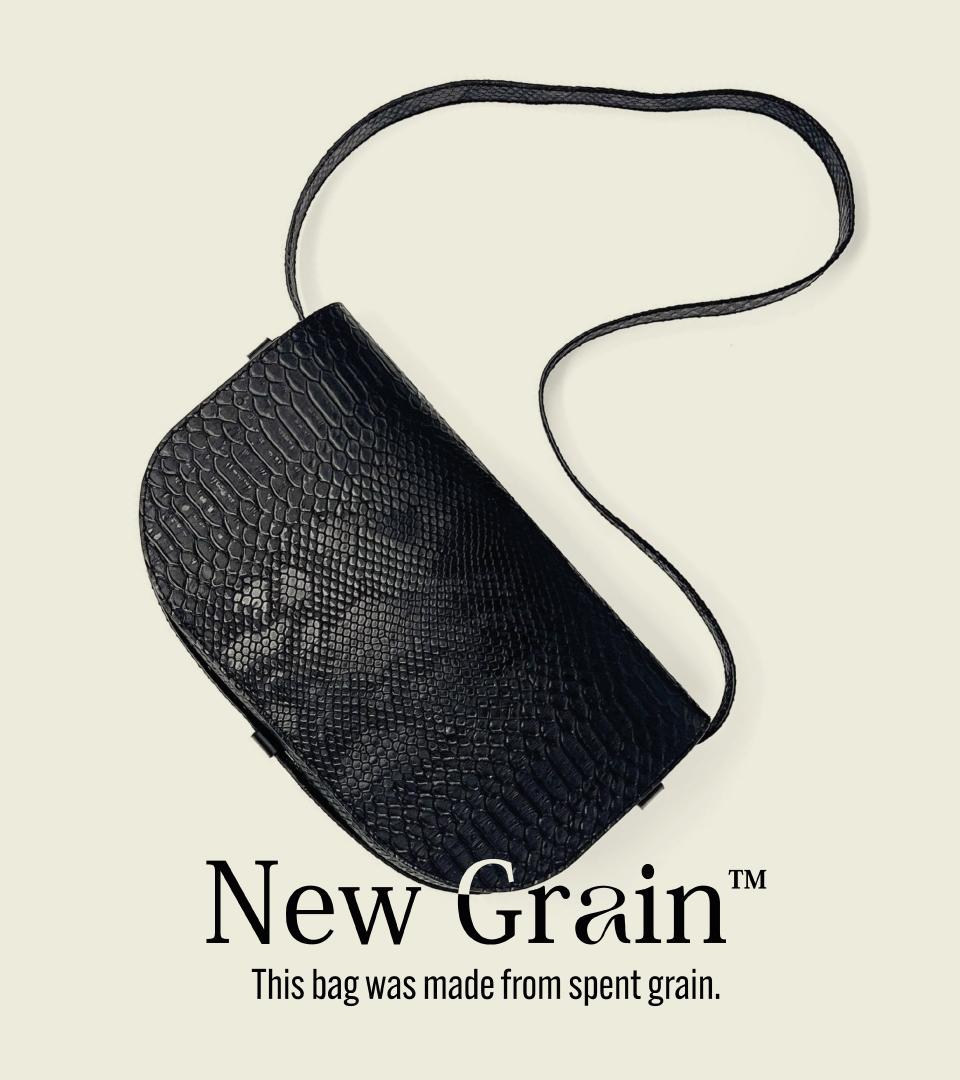

Arda Biomaterials: Brewing Leather Without the Cow

Arda transforms leftover barley from beer and whisky production into New Grain, a plant-protein material that mimics leather without the use of animals or plastics. Every 100 litres of beer leaves behind roughly 20kg of protein- and fibre-rich grain, which Arda upcycles into a durable, customizable leather substitute with natural dark tones and optional finishes. Though still undergoing development, the material is already being trialled in small-edition products like BEEN London’s accessories and a branded holder for Beavertown Brewery.

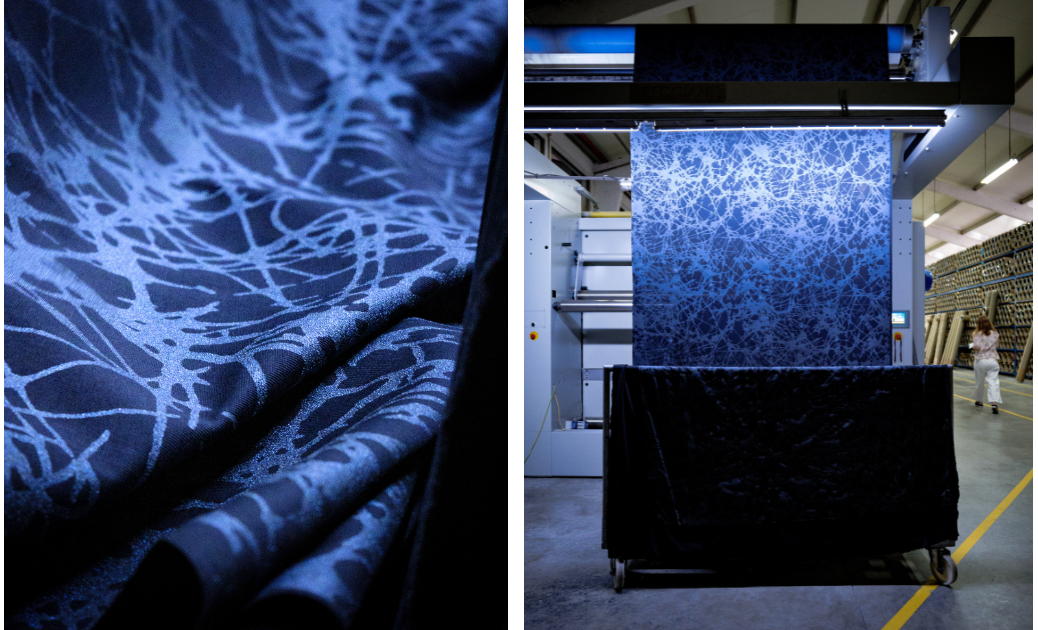

Sparxell: Printing Colour Without the Dye

Sparxell’s structural colour ink isn’t just a pigment, it’s a reinvention of how we apply colour to textiles. Created from engineered plant-based cellulose, the ink mimics natural iridescence, like butterfly wings, to produce vivid hues without using dyes, metals, or plastics. Launched in partnership with Positive Materials, the debut ink is an electric, biodegradable blue that is both matte and shimmering, and fully compostable. It’s designed to work on conventional fabrics like cotton jersey, ready for industrial use. In a world where colour is often chemically heavy and polluting, Sparxell’s ink offers something radical: colour that’s as clean as it is luminous.

HeiQ AeoniQ: The Thread That Might Outrun Polyester

HeiQ AeoniQ isn’t just a fabric innovation, it’s a fibre with a mission. Spun from cellulosic biopolymers, this thread mimics the performance of polyester without using fossil fuels, shedding microplastics, or relying on toxic dyes. Designed to be climate-positive, the raw materials used to make AeoniQ actually absorb CO₂ as they grow. Once disposed of, it biodegrades quickly and safely. It’s closed-loop, scalable, and already backed by big names like Hugo Boss and The Lycra Company. In a textile world hooked on synthetics, AeoniQ is setting a new, cleaner benchmark without compromising on strength or stretch.

AMSilk: Spinning the Future with Bioengineered Silk

AMSilk is rewriting the rules of textile production with its high-performance yarns made from lab-grown silk proteins. Engineered using precision fermentation without relying on animals or plastics, the material mimics the strength and softness of spider silk while remaining entirely biodegradable. These innovative fibres work seamlessly on existing textile machinery, making them both scalable and sustainable. With applications ranging from fashion to automotive interiors, AMSilk’s material is as versatile as it is eco-conscious. And its partnership with Ajinomoto in France signals a major leap in industrial-scale production, paving the way for a cleaner, smarter future in material science.

LVMH: Luxury Rooted in Regeneration

LVMH marked its fourth year at the Future Fabrics Expo 2025 in London by spotlighting material innovation across two key pavilions. One focused on partnerships championing circularity, transparency, low-carbon shipping, and textile reuse, like Weturn and Grain de Sail. The other showcased regenerative agriculture efforts, including sustainable cotton with Söktas and leather with Louis Vuitton. All initiatives align with LIFE 360, LVMH’s environmental roadmap through which the company is aiming towards a transparent change deeply required in the industry.

Why It Matters

If you think about it, materials account for over 70% of a garment’s emissions, and the fashion system remains anchored to fossil-based fibres like polyester. Now these innovators are offering viable alternatives, which are high-performance without compromise, circular, biodegradable, toxin-free, and plant-based, in other words, exactly what the industry has been missing. Moreover, many of these aren’t experimental; they’re industrial-ready. The shift to regenerative feedstocks, biomaterials, and waste-to-resource systems signals a true revolution in how we make clothes.

For more stories of fashion, visit our dedicated archives and stay across our Instagram.